ERW pipe production line’s round-to-square shared roller technology leads industry innovation

In today’s fiercely competitive steel pipe manufacturing industry, how to improve production efficiency, reduce costs and improve product quality has become the focus of every manufacturer. Recently, a technological innovation of round-to-square shared rollers for ERW welded pipe equipment has attracted widespread attention due to its significant advantages.

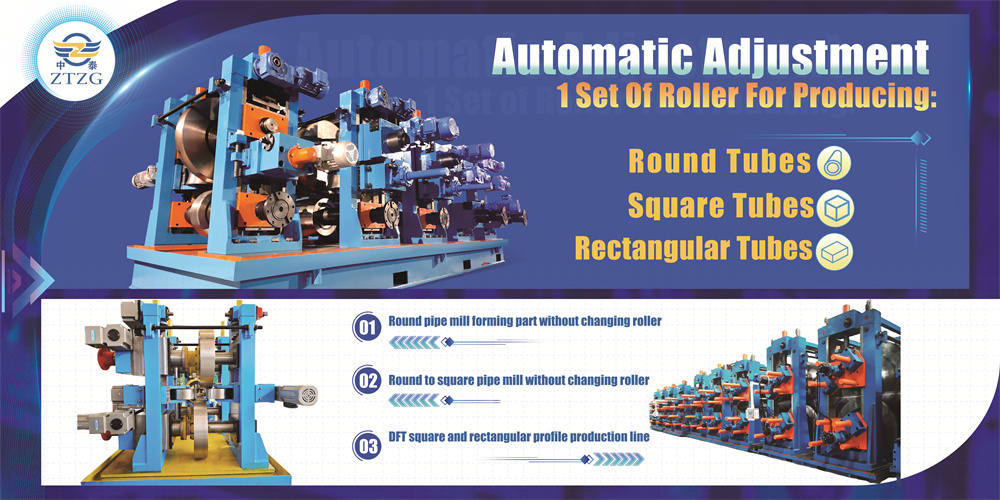

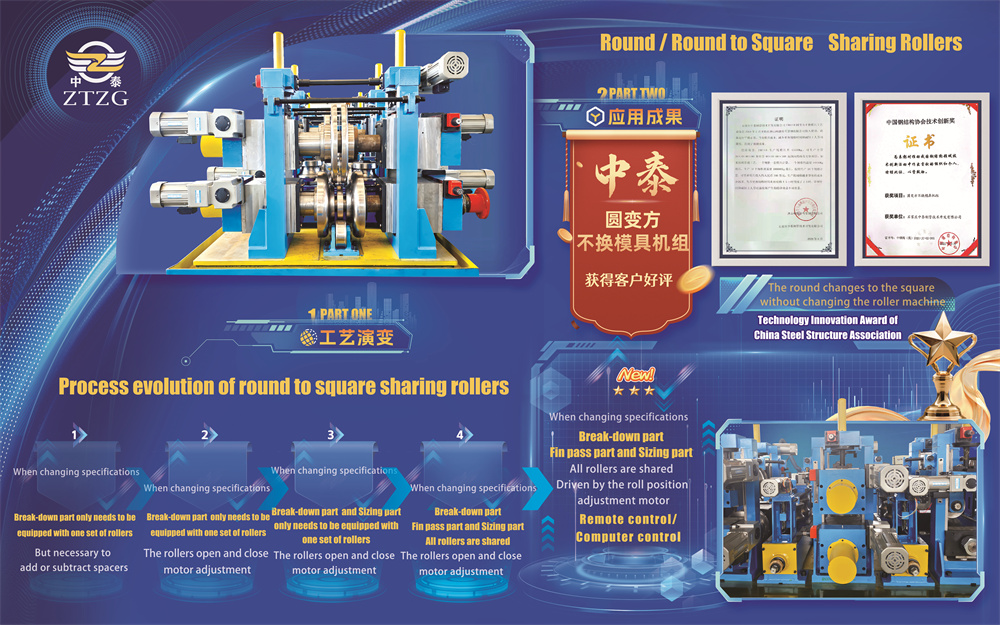

This innovative technology first achieved a breakthrough in the round-to-square process. The traditional round-to-square process usually involves complex roll-changing operations, which is not only time-consuming and labor-intensive, but also increases production costs. The new round-to-square shared roller technology has subverted the traditional model. Through mechanical structure optimization, the sharing of rollers has been realized, greatly improving production efficiency.

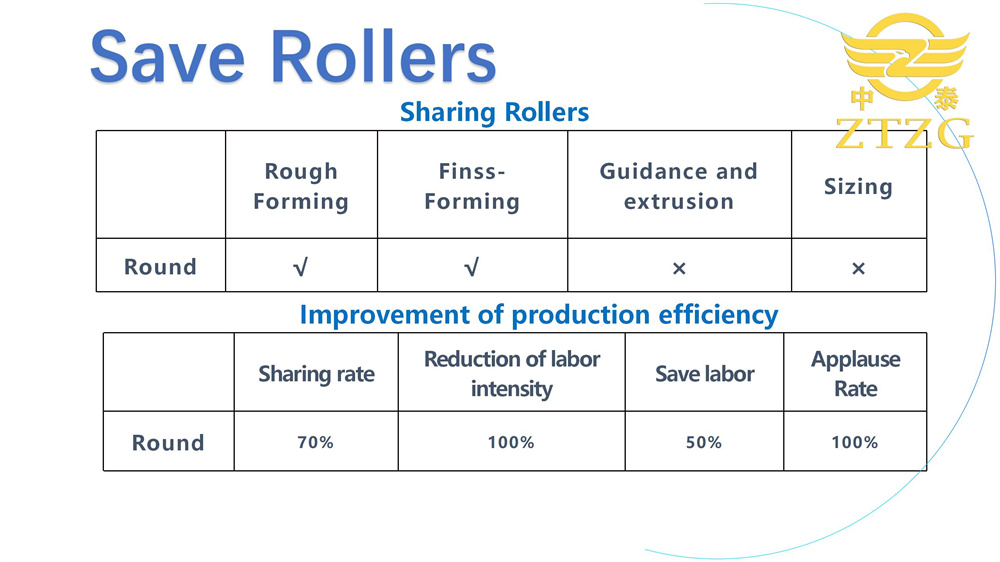

Driven by shared roller technology, production efficiency has been significantly improved. The design of shared rollers requires only one set of rollers for the entire rolling mill, eliminating the need for frequent replacement, reducing mold replacement time and thereby improving the continuous operation capability of the production line. According to the manufacturer, this improvement not only reduces production interruptions, but also enables the equipment to operate more stably, thereby improving overall production efficiency.

Saving production costs is another highlight of this technology. Due to the adoption of shared roller technology, the frequency of mold replacement is greatly reduced, thereby saving mold investment costs. At the same time, this technology also reduces equipment wear, extends equipment service life, and further reduces maintenance costs.

In terms of improving the quality of square tubes, the round-to-square shared roller technology also performs well. Through the optimization of the mechanical structure and the motor-driven rapid roller change system, the corners of the square tube are thickened, the shape is more regular, and the dimensional accuracy is also significantly improved. This not only meets the market demand for high-quality square tubes, but also enhances the market competitiveness of the product.

This innovative technology is particularly suitable for high-end products. As the market demand for high-quality steel pipes continues to grow, the market potential for high-end products is huge. The round-to-square shared roller technology not only improves product quality, but also makes the production of high-end products more economical by reducing costs, opening up new market opportunities for manufacturers.

Motor-driven quick roll change is a core part of this technology. By adjusting the opening, closing, and lifting of the rolls via the motor, workers no longer need to climb high or low. They can quickly complete the roll change operation with just one click, which greatly improves work efficiency and reduces labor intensity.

Since the launch of this innovative technology, it has received unanimous praise from customers. Many manufacturers said that after adopting the round-to-square shared roller technology, production efficiency has been significantly improved, production costs have been significantly reduced, and product quality has also been significantly improved. The successful application of this technology not only brings significant economic benefits to manufacturers, but also sets an example for the transformation and upgrading of the entire steel pipe manufacturing industry.

To sum up, the innovative round-to-square shared roller technology of ERW welded pipe equipment has injected new vitality into the steel pipe manufacturing industry with its unique process advantages, significant production efficiency improvements, cost savings and product quality improvements. In the future, with the continuous promotion and improvement of this technology, I believe that more manufacturers will benefit from this innovative achievement and jointly promote the sustainable and healthy development of the industry

Media Contact

Company Name: Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.

Email: Send Email

Phone: +86-311-85956158

Address:Room 1304 Kaiyuan Building, No.322 East Zhongshan Road

City: Shijiazhuang

Country: China

Website: https://www.ztzgsteeltech.com/