New innovation provides weight savings for applications where size, weight and power (SWaP) are key

Teledyne Labtech announces a major new capability allowing the embedding of layers of synthetic graphite within RF and microwave printed circuit boards (PCBs). Heat management is a significant concern in many aerospace, defense and space applications where size, weight and power (SWaP) are key attributes. Gallium nitride (GaN) solid state power amplifiers (SSPAs) are examples of increasingly common devices that benefit from careful heat management. This new technique allows efficient conduction of heat away from such devices, saving system weight and increasing their lifetime.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20220315005058/en/

Teledyne Labtech Graphite Thermal Management for Microwave PCBs. (Photo: Business Wire)

Managing waste heat is a significant problem in today’s electronic systems, impacting reliability and requiring added expense and weight to control effectively. In the latest consumer mobile phones, it is common to employ sheets of self-adhesive synthetic graphite on top of critical semiconductor devices in order to conduct away waste heat from small areas. Aerospace, defense and space applications require more precision, repeatability and area of coverage. To address this, Teledyne Labtech has developed a method of embedding thin layers of synthetic graphite inside the structure of the host PCB reliably, saving size and weight, while increasing the lifetime of active devices (MTBF) by permitting operation at cooler steady state.

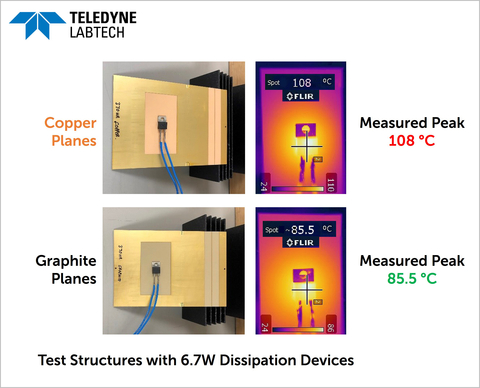

“Synthetic graphite is 4 times lighter than copper, and transfers heat 4 times better in the X-Y plane,” said John Priday, CTO of Teledyne Labtech. “Replacing PCB ground plane layers with it in critical applications such as T/R modules can cause devices to run up to 20°C cooler in our testing.”

Labtech has demonstrated that thermal copper layers can be replaced with the new graphite technique while remaining reliable and experiencing minimal impact on the passage of microwave signals on grounding layers.

Teledyne Labtech will be available to discuss this new innovation at Booth 1324 of the Satellite Show in Washington, DC, March 22nd-24th.

ABOUT TELEDYNE LABTECH

Teledyne Labtech has over 30 years of experience as a world leader in microwave circuit design, component manufacturing and testing in the defense, electronics, global telecommunications, space and satellite communications markets. As with all Teledyne Labtech production operations, this contract award will be performed at Teledyne Labtech’s state of the art facility in Presteigne, Wales, UK. For more information, visit www.teledynelabtech.com

ABOUT TELEDYNE DEFENSE ELECTRONICS

Serving Defense, Space and Commercial sectors worldwide, Teledyne Defense Electronics offers a comprehensive portfolio of highly engineered solutions that meet your most demanding requirements in the harshest environments. Manufacturing both custom and off-the-shelf product offerings, our diverse product lines meet emerging needs for key applications for avionics, energetics, electronic warfare, missiles, radar, satcom, space, and test and measurement. www.teledynedefenseelectronics.com/.

View source version on businesswire.com: https://www.businesswire.com/news/home/20220315005058/en/

Contacts

Sharon Fletcher

Teledyne Defense Electronics

+1 323-241-1623 sharon.fletcher@teledyne.com